来源:中科煜宸 作者:中科煜宸 时间:2025-01-09 11:30:17 已阅:0次

Formnext 2024国际精密成型及3D打印制造展览会于11月19日在德国法兰克福盛大开幕。作为全球规模最大的3D打印专业展会,Formnext被誉为行业的“奥斯卡”,集中展示了增材制造领域的最新技术和前沿应用,吸引了众多国际企业和行业专家的积极参与。

The Formnext 2024 International Precision Molding and 3D Printing Manufacturing Exhibition officially opened on November 19 in Frankfurt, Germany. As the largest 3D printing trade show in the world, Formnext is often referred to as the "Oscar" of the industry, showcasing the latest technologies and cutting-edge applications in additive manufacturing. It has attracted active participation from numerous international companies and industry experts.

今年是中科煜宸第二次亮相formnext展会,借助这一具有全球影响力的平台,中科煜宸再次向北欧及全球用户展示其在金属增材制造领域的最新技术和产品,凭借创新实力圈粉。

This year marks the second appearance of Zhongke Raycham at the Formnext exhibition. Leveraging this globally influential platform, Zhongke Yuchen once again showcased its latest technologies and products in the field of metal additive manufacturing to Nordic and global users, winning attention with its innovation.

DED 3D PRINTING

送粉3D打印技术强势“圈粉”

作为送粉增材制造装备及技术的领军企业,此次展会中科煜宸带来了LDM16RD激光精密增材修复装备以及送粉3D打印技术在航空航天、汽车、船舶、冶金、模具等工业制造领域的最新应用案例。

As a leading company in powder feeding additive manufacturing equipment and technology, Zhongke Raycham brought its LDM16RD laser precision additive repair equipment to the exhibition, along with the latest application cases of powder feeding 3D printing technology in industries such as aerospace, automotive, shipbuilding, metallurgy, and mold manufacturing.

LDM16RD采用小型高柔性机器人与高精度双轴变位机联动结构工作,采用环形送粉或光内送粉精细熔覆头,可满足航空航天及其他精密修复与打印领域多种金属材料的沉积需求,极大缩减维修时间和成本。通过LDM16RD设备的现场工作演示,让参观者直观感受了设备的精致小巧、功能强大,吸引了众多客户、同行、观众的咨询与交流。

The LDM16RD features a compact, highly flexible robotic system integrated with a high-precision dual-axis positioning machine. It utilizes either an annular powder feeding or laser internal powder feeding fine cladding head, which meets the deposition needs of various metal materials for aerospace and other precision repair and printing applications, significantly reducing maintenance time and costs. Through on-site demonstrations of the LDM16RD, visitors were able to experience firsthand the equipment's compact design, powerful functionality, and were drawn to engage in consultations and discussions, attracting numerous customers, industry peers, and attendees.

钛合金具有低密度、高强度、耐腐蚀等特性,制成的手机外框坚固耐用。采用送粉3D打印钛合金手机外框,能精确控制材料使用,减少浪费,降低原材料成本,可以大大缩短制造周期,尤其适合小批量、定制化生产,能快速响应市场变化和个性化需求。

Titanium alloy is characterized by low density, high strength, and corrosion resistance, making it an ideal material for durable phone casings. Using DED 3D printing for titanium alloy phone frames allows for precise material control, reducing waste and lowering raw material costs. It can significantly shorten the manufacturing cycle, especially for small-batch and customized production, enabling quick responses to market changes and personalized demands.

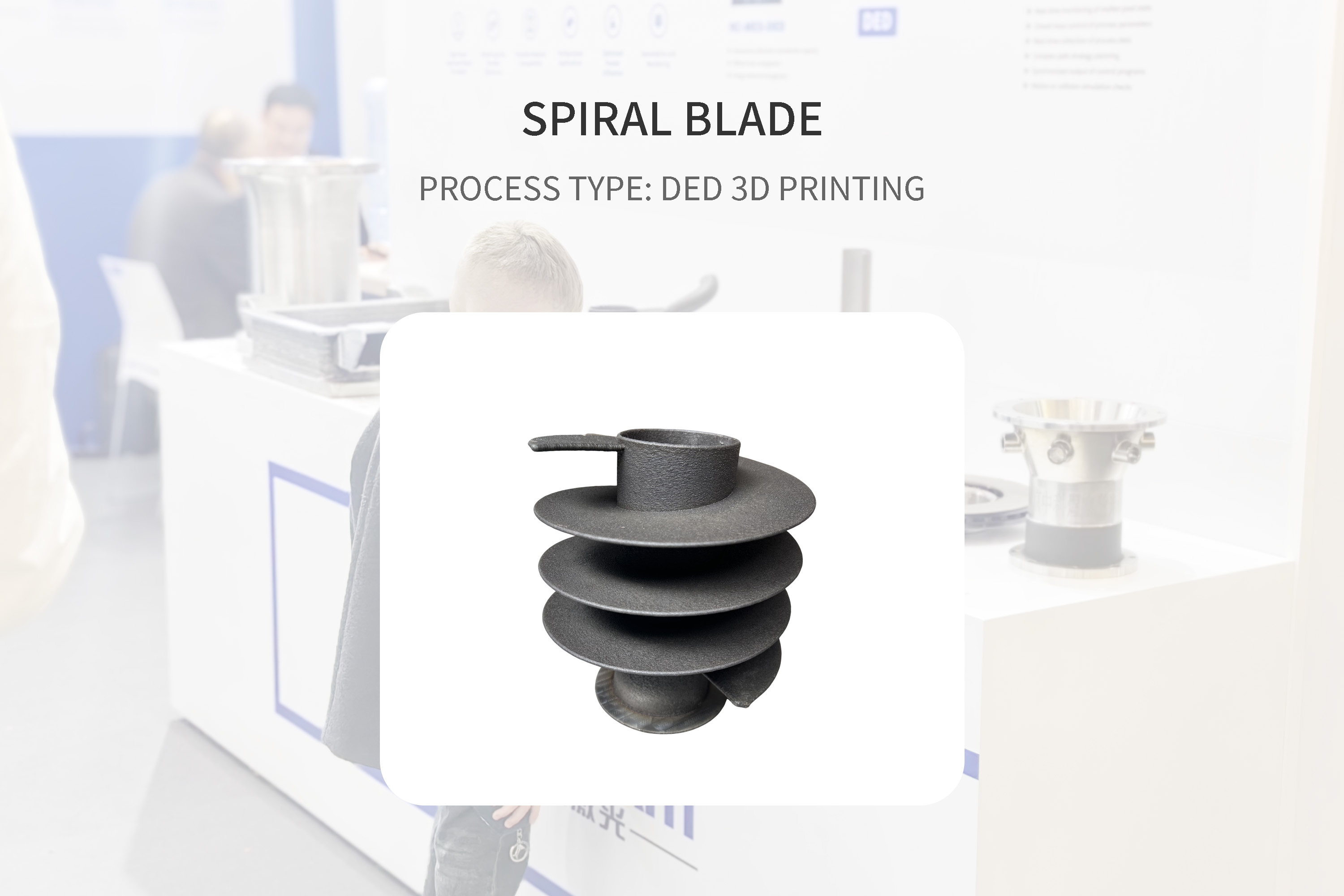

叶片呈螺旋形状,围绕中心轴旋转,可实现物料的连续输送与推送,广泛应用于矿山、化工、农业、环保、建筑桩基工程、电子等行业 。采用送粉3D打印技术,成型精度高,装配简单、快捷,可提高生产效率,降低生产成本。

The blades are spiral-shaped and rotate around a central axis, enabling continuous material delivery and pushing. This design is widely used in industries such as mining, chemicals, agriculture, environmental protection, construction piling, and electronics. By utilizing powder feeding 3D printing technology, the molding precision is high, and assembly is simple and fast, which helps improve production efficiency and reduce manufacturing costs.

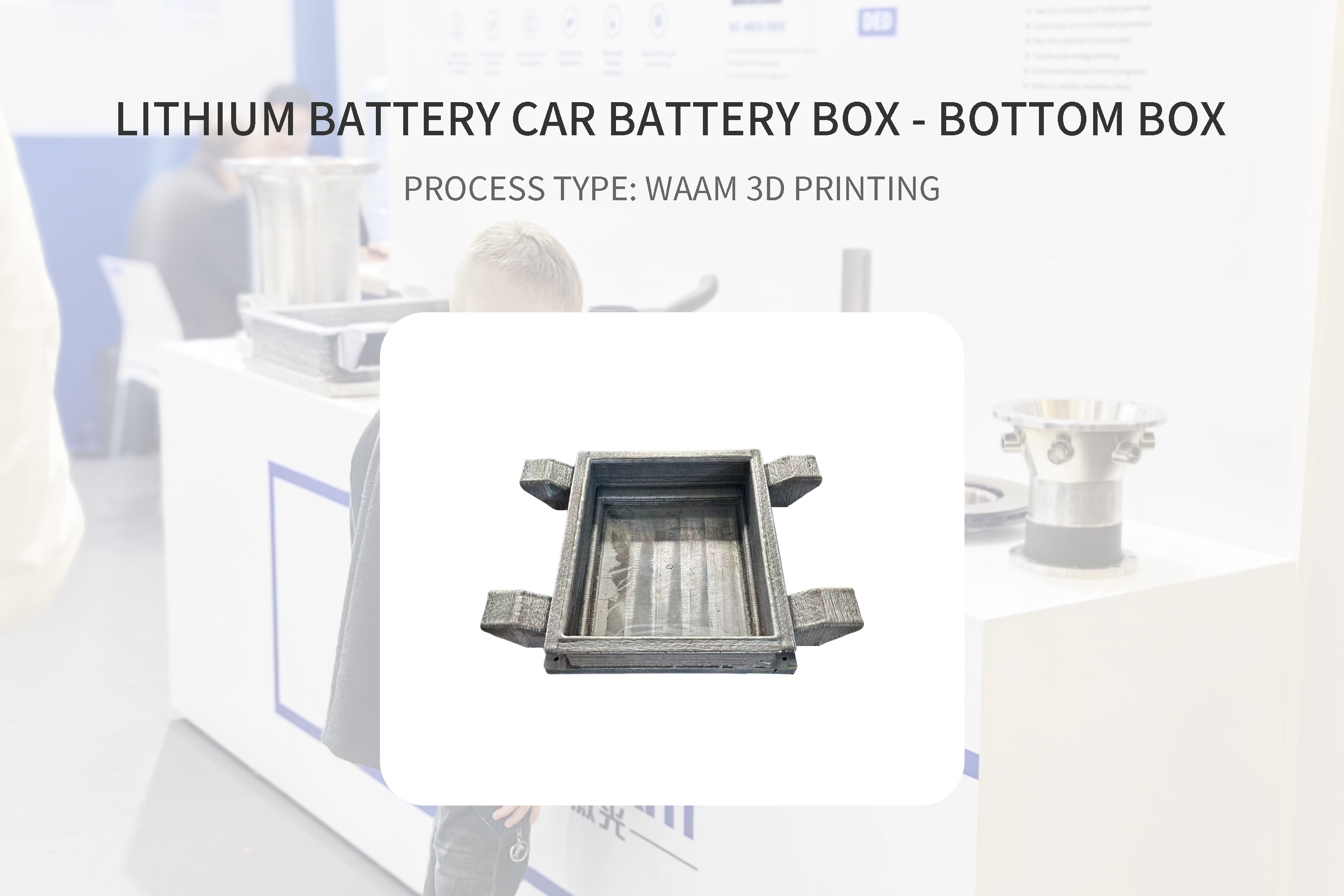

电弧3D打印使电池底盒的强度重量比更优,在减轻重量的同时,能更好地承受车辆运行中的震动、冲击和压力 ,保护电池安全。可根据不同车型的空间布局、电池形状和性能要求,快速设计并打印出相应的电池底盒,缩短生产周期,提高生产效率;且原材料利用率高,浪费少,降低了材料成本。

WAAM 3D printing improves the strength-to-weight ratio of battery bottom boxes, making them lighter while better able to withstand vibrations, shocks, and pressure during vehicle operation, thereby ensuring battery safety. It allows for the rapid design and printing of customized battery bottom boxes based on the space layout, battery shape, and performance requirements of different vehicle models, shortening production cycles and increasing manufacturing efficiency. Additionally, the high material utilization rate and low waste help reduce material costs.

刹车盘高速激光熔覆技术可以减少制动粉尘、增加使用寿命、提升安全性能。借助于高速工艺,最薄熔覆层在100 μm范围内,满足灰铸铁熔覆层的周期时间要求;可减少高达60%的细微颗粒物并能提升3倍的刹车片耐磨性。

High-speed laser cladding technology for brake discs can reduce brake dust, extend service life, and improve safety performance. With the high-speed process, the thinnest cladding layer is within the 100 μm range, meeting the cycle time requirements for gray cast iron cladding. This technology can reduce fine particulate matter by up to 60% and increase brake pad wear resistance by three times.

除此之外,中科煜宸还带来了铺粉3D打印技术在航空航天、汽车、模具等工业制造领域的应用,如叶片、尾喷管、排气歧管、鞋模、汽车轮胎模等。中科煜宸能有效满足用户多样化生产需求,助力生产降本增效,让生产过程更节能、更环保,驱动制造行业智造升级。

In addition, Zhongke Raycham also showcased the application of SLM 3D printing technology in industries such as aerospace, automotive, and mold manufacturing, including components like blades, tail nozzles, exhaust manifolds, shoe molds, and automotive tire molds. Zhongke Raycham is able to effectively meet the diverse production needs of users, helping to reduce costs and improve efficiency, making the production process more energy-efficient and environmentally friendly, and driving the intelligent upgrade of the manufacturing industry.

RAYCHAM & SYNOVA

与Synova联合展出水导激光技术

Synova作为水导激光的创始单位,拥有全球最先进的水导激光系统。中科煜宸是Synova的OEM合作伙伴,中科煜宸在本土开发水导激光设备,可以得到Synova的国际认证,共同面向全球销售。

As the founding entity of water-assisted laser technology, Synova possesses the world’s most advanced water-assisted laser systems. Zhongke Raycham is an OEM partner of Synova and has developed water-assisted laser equipment locally. This allows Zhongke Yuchen to obtain Synova’s international certification and jointly sell the products globally.

此次展会,中科煜宸与Synova联合展出了水导激光加工设备,并展示了其在复合材料、热障涂层、半导体/陶瓷、金刚石以及多种脆硬材料上的加工优势,吸引了众多专业人士的关注。

At this exhibition, Zhongke Raycham and Synova jointly showcased water-assisted laser processing equipment and demonstrated its processing advantages on composite materials, thermal barrier coatings, semiconductors/ceramics, diamonds, and various brittle and hard materials, attracting the attention of many industry professionals.

中科煜宸始终坚持以市场需求为导向,不断加大科研创新力度,为用户提供增、等、减材全方位一体化解决方案。此次亮相德国Formnext展会,不仅展示了自身创新实力,与国际同行进行了深入的交流和合作,也进一步拓展了在国际市场的品牌影响力。

Zhongke Raycham has always adhered to a market-driven approach, continuously enhancing its research and innovation efforts to provide users with comprehensive, integrated solutions for additive, subtractive, and material processing. Its appearance at the Formnext exhibition in Germany not only showcased its innovative strength but also facilitated in-depth exchanges and cooperation with international peers, further expanding its brand influence in the global market.

_____

展会还在进行,更多精彩展品等您来看,中科煜宸在11.0馆C39展位期待您的莅临!

The exhibition is still ongoing, with more exciting exhibits waiting for you to explore. Zhongke Raycham looks forward to your visit at Booth C39 in Hall 11.0!